Bag filters are high-efficiency air filters used to capture fine dust, particles, and suspended contaminants in HVAC systems.

What Is a Bag Filter?

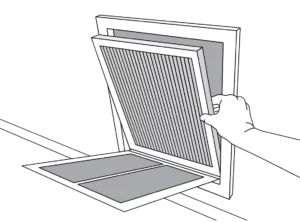

Bag filters consist of multiple synthetic or fiberglass filter pockets mounted inside a rigid galvanized or plastic frame.

Thanks to their extended surface area, they offer high filtration performance with low pressure drop.

Technical Specifications

| Feature | Description |

|---|---|

| Filtration Class | F5 – F9 (ISO ePM10, ePM2.5, ePM1) |

| Filter Media | Synthetic fiber or microglass fiber |

| Pocket Depths | 300 mm, 400 mm, 600 mm (custom options available) |

| Frame Material | Galvanized steel, plastic, or aluminum |

| Recommended Life | 6–12 months depending on application and dust load |

| Airflow Range | From 1000 m³/h to 3600 m³/h depending on model and size |

Where Are Bag Filters Used?

-

Shopping malls, hotels, hospitals, and schools

-

Pharmaceutical and food production facilities

-

Paint booths and automotive manufacturing plants

-

Cleanrooms and laboratory air handling systems

-

Data centers and server rooms

Types of Bag Filters

Bag filters are available in different grades and configurations:

-

F5–F6 (ISO ePM10): Pre-filtration of medium particles

-

F7–F8 (ISO ePM2.5): Effective for fine dust and pollutants

-

F9 (ISO ePM1): Suitable for critical applications like clean air zones

Each type is designed to meet specific air quality standards in accordance with EN 779 / ISO 16890.

Advantages of Using Bag Filters

Extended surface area for higher dust retention

Energy-efficient operation due to low pressure drop

Long service intervals (6–12 months)

Available in various sizes and filtration classes

Easy to install and replace

Optional flame-retardant media available

How to Select the Right Bag Filter?

When selecting a bag filter, consider

-

Required filtration class (F5–F9)

-

Airflow capacity (m³/h)

-

Pocket length (depth)

-

Type of airborne contaminants (dust, smoke, chemicals)

-

System compatibility (frame dimensions and sealing type)

Frequently Asked Questions

Q: How often should I replace a bag filter?

A: Typically every 6–12 months, depending on dust load and system design.

Q: What is the difference between synthetic and fiberglass media?

A: Synthetic media is lightweight and cost-effective, while fiberglass offers better thermal resistance and filtration stability.

Q: Can bag filters be custom-sized?

A: Yes. At Dinamik Filtre, we manufacture bag filters in standard and custom dimensions based on your system requirements.

Contact Us for Custom Production

Dinamik Filtre provides durable and efficient bag filters designed for industrial and commercial HVAC applications.

We offer fast production, technical support, and high-capacity models tailored to your needs.

📞 +90 212 281 12 23

📧 [email protected]

🌐 www.dinamikfiltre.com